Gravimetric dosing technology fitted for your production

Batch weighers

with integrated V2a agitator

drum /

mixing drum

The

gravimetric batch weighers of the series DW-T are dosing systems

especially developed fo rmixing-and problem materials.

"Especially suitable for: tea and spice mixtures, herbs, friction linings (brake and clutch linings) carbon fiber, mixing all kinds of materials and badly flowing bulk materials”

standard sizes: 30 liters; 100 liters; 200 liters; other sizes on request

The weighing material will be transported out of the agitator drum by a conveying system in to the weighing pan. The material will be transported in two phases, rough and fine dosing. After reaching the given set weight the weigher waits for an external command (e.g. of a press or a packaging machine) which allows the discharge.

A new weighing cycle follows automatically.

conveyor systems: belts, vibration channels, vibration belts and

dosing screws

additional modules: distribution systems, coordinate tables, turntable, conveyor belts (on request)

options: customized adaptations

Dosing weigher KDW 0.5/T-30

Plant

construction

here: especially for dosing of carbonAluminum profile frame,

agitator drum in V2a with appr. 30 liters volume,

conveying channel with vibrator,

electronic weighing system with automatic discharge,

and weighing pan with appr. 500 ccm volume

all product touching parts in stainless steel V2a (material no: 1.4301)

dosing

control via dosing processor

DPC 3001

Batch weigher

DW

2.0/T-100/SP

agitator drum in V2a with appr. 100 liters volume,

dosing system: rough/fine dosing channel with vibrator,

and weighing pan with appr. 2000 ccm volume

all product touching parts in stainless steel V2a (material no: 1.4301).

weighing range: 1500 g

cycle time: appr. 8 - 10 weighments per minute

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending

on the product

Batch weigher DW 1.5/T-100/DT-12 with 12-station turntable

Plant construction here: especially for brake liningsAluminum profile frame

agitator drum in V2a with appr. 100 liters volume,

dosing system: rough/fine dosing channel with vibrator,

electronic weighing system with automatic discharge,

and weighing pan with appr. 1500 ccm volume

12-station turntable for filling customer's cup

(material no: 1.4301) without drum

weighing range: g

cycle time: appr. 12 weighments per minute

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending

on the product

Batch weigher DW 0.5/T200/DT-12 with

12-station

turntable

Plant

construction

here: especially for

friction liningsAluminum profile frame,

agitator drum in steel with appr. 200 liters volume,

dosing system: Rough/fine-dosing screws instead channels

with vibrators

and weighing pan with appr. 500 ccm volume

12-station turntable for filling customer's cup

all product touching parts in stainless steel V2a

(material no: 1.4301) without drum

weighing range: g

cycle time: appr. 12 weighments per minute

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

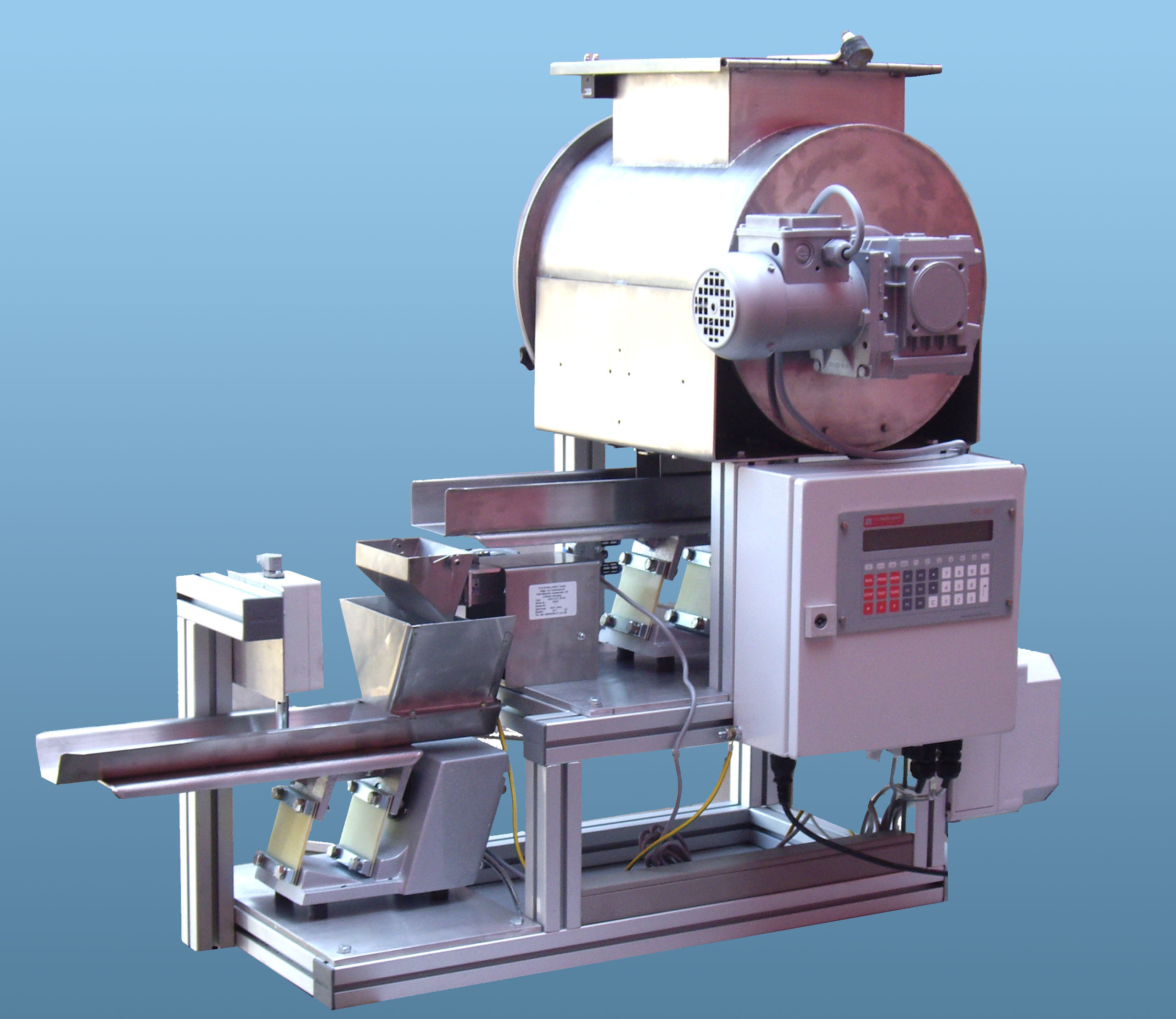

Gravimetric Double -Dosing -Unit with X-Y Coordination Desk TYPE DDW 0.5/T-100 KT

Case study: Position of friction material (brake linings and clutch facings) from25 g – 200 g in different explacements

Movable solid Aluminium profil-shaped frame

Special designed 100 litres agitator drum

Minimum- and maximum level-control sensors for agitator drum (optional)

Rough/fine-dosing screws instead channels with vibrators

Two electronic weighing systems with automatic discharge and weighing pans with 500 ccm volume

Dust-protection X-Y co-ordination desk for automatic charging in forms from 20 – 36x.

Dosing processor DPC 3000 with external operator panel -folied keybord - LCD-Display

Telefon: 0911 - 96 44 936 Telefax: 0911 - 96 44 938 E-Mail: info@ktg-engelhardt.de www.ktg-engelhardt.de

| Contact | Location | Imprint | AGB's |