Gravimetric dosing technology fitted for your production

Check-weigher type APW and PW

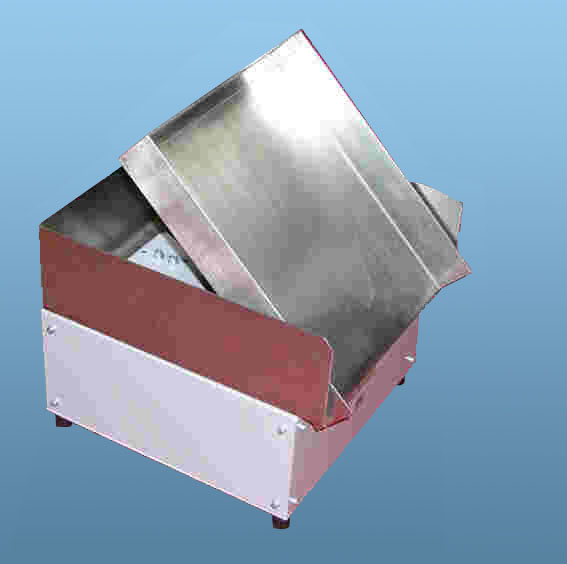

The robust check-weigher is constructed for the rough production area. The short weighing cycles garantee a very short machine stand-by time. The automatic tare function enables false weighing results if castings are inadvertently left on the weighing platform or in the weighing pan. The output datas from the standard interface can be used for documentation or for controlling a followed sorting machine. In this way the normal check-weigher will be also a qualitycontrol weigher of the products.

Function:

The check-weigher had to be connected in line with the diecasting machines. The registrated set weight of the production parts will be compared with the preselected min/max weights. If the true weight do not compares with the invoked tolerances the closing contact for the diecasting machine is hold in the off position and the production can be stopped. If the true weight is detected as "good", the machine gets the closing contact.

inlethopper (rectangular shape) 200 mm x 135 mm,

weighing pan with appr. 1000 ccm volume,

precision electronic weighing system with pneumatic discharge (6 bar),

product touching parts in stainless steel V2a,

controled via dosing processor DPC 3001,

electronic

control device with foiled keybord,

LCD – display,

art of protection IP 54

weighing range: up to 200 g,

accuracy: +/- 50 mg,

resolution: 10mg,

cycle time: appr. 10 - 15 weighments per min.

performance and accuracy specifications are depending on product).

short description type APWIII/WT

weighing plate 320 x 280 x 50 mm,

precision electronic weighing system with automatic discharge,

product touching parts in stainless steel V2a,

controled via dosing processor DPC 3001,

electronic control device with foiled keybord, LCD – display,

art of protection IP 54,

positive locking enable pulse,

weighing range: up to 1000 g,

accuracy: +/- 500 mg,

resolution: 100mg,

cycle time: appr. 10 weighments per min.,

(performance and accuracy specifications are depending on product).

short

description type APWIII/WT-SK

weighing plate 320 x 280 x 50 mm,

sorting flap for good / bad excretion,

precision electronic weighing system with automatic discharge,

product touching parts in stainless steel V2a,

controled via dosing processor DPC 3001,

electronic control device with foiled keybord, LCD – display,

art of protection IP 54,

weighing range: up to 1000 g,

accuracy: +/- 500 mg,

resolution: 100mg,

cycle time: appr. 10 weighments per min.,

(performance and accuracy specifications are depending on product).

Telefon: 0911 - 96 44 936 Telefax: 0911 - 96 44 938 E-Mail: info@ktg-engelhardt.de www.ktg-engelhardt.de

| Contact | Location | Imprint | AGB's |