Gravimetric dosing technology fitted for your production

Batch Weighers DW 0.1 between 0,5 g up to 80 g

Batch Weighers

DW between 5 g up to 5000 g

Batch Weighers DW 2-f.,/3-f./4-fold

"New" especially for flour and dusty products

Bag Filling weighers of series BP

outside of our standard equipment we offer

customizeffd solutions

Function Batch weigher

The material will be

transported out of the hopper (option with level control) by

a conveying system into the weighing pan.The material will be

transported in two phases,

rough- and fine dosing. After reaching the given set weight the

weigher waits for an external command which

allows the discharge (e.g. of a press or a packaging machine). A new

weighing cycle follows automatically.

As conveying systems:

belts, vibration channels, vibration belts and screw conveyors.

ADDITIONAL EQUIPMENT:

Distributing systems, coordination tables, turntables, conveyor belts

Gravimetric

batch weigher DW 0.1 for smallest quantities DW

0.1

The requirements of

accuracy concerning dosing weighers are more and more important.The DW

0.1 satisfies

these high quality requirements.The high soluted electronic weighing

obtains an accuracy up to 0.1% for weighing quantities between 0.5

g up

to 50

g).

The compact batch weigher is built-up by a closed solid housing with a removable macrolon casing.There fore an easy access for the cleaning and maintenance work is guaranteed.This fact is an advantage if you want to change the product.

weighing

range: 0,5 g to 80 g

cycle

time:

appr. 12

weighments per minute

stocking:

3 liters rectangular

hopper

parts in contact with stainless steel

V2A (material no. 1.4301)

dimensions: appr. 500

mm x 180 mm x 450 mm

weight: appr. 12 kg

dosing control via

dosing processor DPC 3001

Gravimetric batch weigher DW 0.1/TB-750 for smallest quantities with conveyor belt (here specifically globules filling)

robust aluminum base plate for weigher and conveyor belthopper with appr. 3 litres volume

dosing system: rough/fine dosing channel with vibrator

electronic weighing system with automatic discharge

weighing pan with appr. 80 ccm volume

discharge chute made of stainless steel for customer vials

conveyor belt with drive motor: length: 750 mm width: 140 mm

overall dimensions of the unit: appr.: l: 800 mm x w: 500mm x h: 800 mm,

all product touching parts in stainless steel V2a (material no: 1.4301)

weighing range: 40 g

cycle time: appr. 12 weighments per minute

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

Batch weighers of series DW

are

discontinuous dosing systems for all kinds of bulk materials with batch

between 5 g up to 5000 g. The advantage of the high soluted electronic

weighing is the weighing accuracy up to 0,05%. All DW – dosing systems

are low-wear and almost maintence-free. The parts which come into

contact with the product are easy to clean. This fact is an advantage if

you want to change the product. weighing range: 5 g to 5000 g

cycle time: appr. 10 - 15 weighments per minute

stocking: 30 liters or 60 liters rectangular hopper

overall dimensions of the unit (without controller)

appr.: l: 900 mm x w: 400 mm h: 800 mm

parts in contact with stainless steel V2A (material no. 1.4301)

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

“New" especially for flour

and dusty

products

Bag Filling weighers of

series BP

are discontinuous bag filling weighers especially for

customer

block

bottom bags

or

bags.The product will be transported out of the material hopper by a conveying system directly into the block bottom bags/bags and weighed. After reaching the final weight of the bag is removed and clamped a new bag. Pressing the food-contact-switch or pushbutton, a new weighing procedure is initiated.

weighing range: 5 g to 5000 g

cycle time: appr. 6 - 8 weighments per minute

stocking: 50 liters rectangular hopper

overall dimensions of the unit (without controller)

appr.: l: 950 mm x w: 400 mm h: 800 mm

all product touching parts in stainless steel V2a (material no: 1.4301).

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

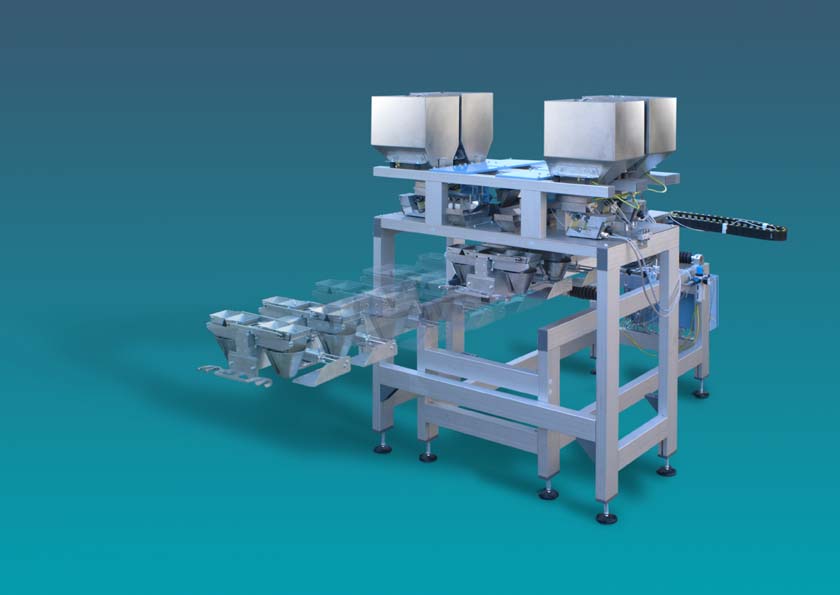

Batch weighers of series DW 2-f./3-f./4-fold

Plant construction here:

hopper with appr. 120 litres volume

3 x dosing system: rough/fine dosing channel with

vibrator

3 x electronic weighing system with automatic

discharge

3 x weighing pan with appr. 1000 ccm volume

all product touching parts in

stainless steel V2a (material no: 1.4301).

weighing range: 500 g

cycle time: appr. 30 weighments per minute

dosing control via dosing processor DPC 3001 performance and accuracy specifications are depending on the product

gravimetric batch

weigher DW 0.1/DT-12 for smallest quantities

with 12-station turntable

Plant

construction

here:with 12-station turntable

hopper with appr. 3 litres volume

dosing system: rough/fine dosing channel with vibrator

electronic weighing system with automatic discharge

and weighing pan with appr. 80 ccm volume

12-station turntable for filling vials

all product touching parts in stainless steel V2a (material no: 1.4301).

weighing range: 40 g

cycle time: appr. 12 weighments per minute

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

Gravimetric 4 -Component Dosing Unit with Integrated X-Y Linearsystem Type DW 0.2 / 2 x 2-f

Case study: dosing of powder / granulat 2g - 3,5g and 40g - 75gSolid Aluminium profil – shaped frame

Rectangular hoppers with 20 litres volume

Four rough/fine-dosing channels with vibrators (for explosive atmospheres)

Four electronic weighing system with automatic discharge and weighing pan with 200 ccm volume

X-Y linearsystem for driving the material into customer form

All material contacted parts stainless steel made

Dosing processor DPC 3000 in control box integrated

External operator panel with folied keybord - LCD-Display

Control box with front door dims: b: 600 mm, d: 600 mm, h: 2000 mm

Whole equipment for working in explosive atmospheres

Connection of equipment on Simatic-control-system S7/315-2DP

Including customer specific software

Gravimetric Dosing Unit Type DW 3.0/Special with Lifting Unit Type HE/2600

Case study:: dosing of agglomerate and powder appr. 1 kg/min bulk density appr. 2 – kg/dm3Rectangular hopper with 200 litres volume, incl. min.-levelsensors and broken-end collecting

device, four pillars with leveling foots and flaps forstacking truck

Hopper inside with pillar-pressure-relief and lattice-rust

Conveying channel with wearing plate and strengthen vibrator

Rough/fine-dosing channel b: 100 mm with strengten vibrator

Electronic weighing system with weighing platform 3000 ccm volume and automatic tipping

device with pneumatic operation

Lifting device (lifting heighth 2600 mm): linear axle with pneumatic impulse

Reception for tipping pan with discharge system

Movable aluminium profile for vibrators, weighing system and tipping device

Dust-proof protection with broken-end collecting device for the whole material-conveying-distance

All material contacted parts stainless steel made

Dosing processor DPC 3000, IP 21, plug & work unit incl. 10 m connection cable

Controlling of tipping device and customer hydraulic-elevator-controller with dosing processor DPC 3000

Telefon: 0911 - 96 44 936 Telefax: 0911 - 96 44 938 E-Mail: info@ktg-engelhardt.de www.ktg-engelhardt.de

| Contact | Location | Imprint | AGB's |